RESISTANCE WELD TECHNOLOGY

Parker Canada is committed to offering the Automotive Industry the most comprehensive array of motion control products and technologies. Parker is continuously improving the performance and value of our products and services to meet current and future needs of the global Automotive Industry.

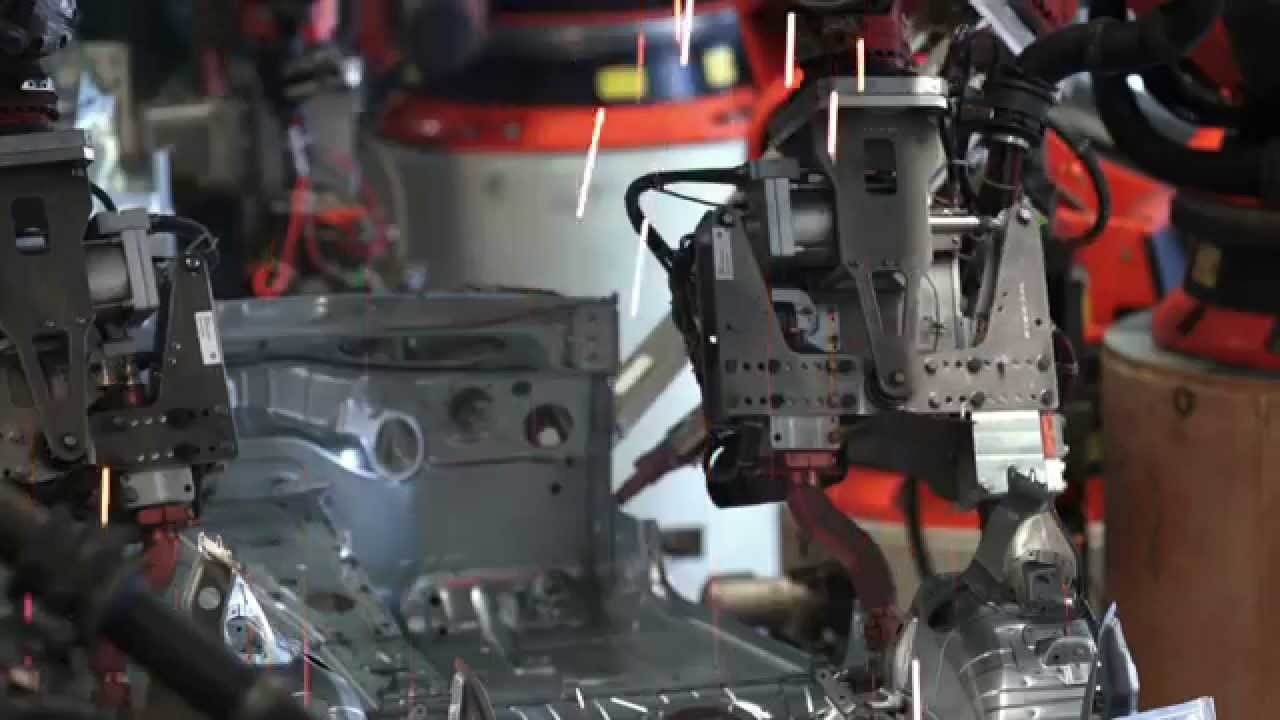

Parker Automotive manufacturing focus includes body and assembly, power train, metal stamping, components and trim. Our deep understanding of spot welding applications and our motion and control expertise helps us produce both standard and custom weld control packages that exceed customer expectations.

Water Block

Designed for Automotive welding applications, Parker's WBB Water Block is an integrated manifold that supplies and monitors water to provide essential protection to expensive welding equipment.

Water Retract Actuator

Parker's WRA Water Retract Actuator stops weld water expulsion. The integral design allows for dry weld tip changes and keeps water off your equipment, and out of your cell.

How does it work?

For a typical tip changeover without a Parker Water Retract Actuator, water is turned off and the weld tip is removed. This results in water being expelled from the weld gun tip. 160ml of water is the typical amount expelled.

For a typical tip changeover with a Parker Water Retract Actuator (WRA250), water is turned off, the Parker Water Retract Actuator is enabled and the weld gun tip is removed. This results in virtually no water being expelled from the weld gun tip.

It is easy to see the total amount of water and clean up labour saved when your facility has hundreds of weld guns and thousands of tip changes per day.

Water Retract Actuator prevents excessive water spills and helps to alleviate safety concerns

The innovation is ideal for busy automotive body-in-white shops; for example, excessive water spillage within a weld cell environment can present a number of hazards, including electrical shock, slip danger, equipment damage and, potentially, the manufactured product being scrapped. The WRA works by cleverly reducing the water pressure in the closed loop cooling circuit. This has the effect of eliminating the problems of water being expelled under pressure during a tip change. See how Parker can help you solve the problem while increasing safety.

Email: pcdmktg@parker.com

Ph: 905-693-3020